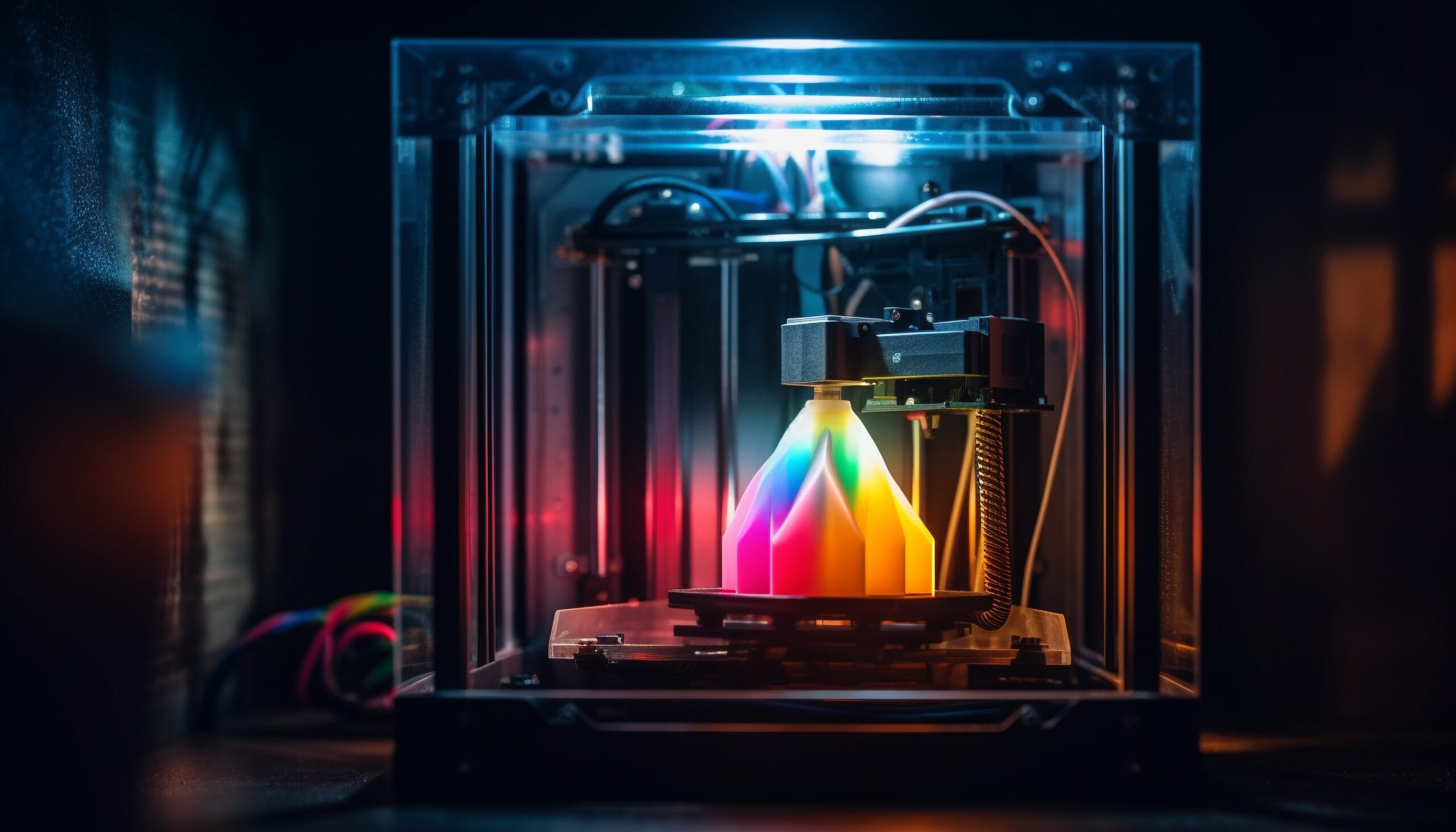

Introduction to Medical Devices: The Evolution of 3D Printing Technology

In recent years, the healthcare landscape has experienced rapid transformations, particularly with the advent of 3D printing technology. As we look ahead, it becomes increasingly clear that this innovative approach will play a pivotal role in shaping the future of medical devices. Not only does 3D printing allow for unprecedented levels of customization, but it also enhances the efficiency of manufacturing processes.

Moreover, this technology enables the production of complex geometries that were previously unattainable through traditional methods. Consequently, healthcare professionals can create medical devices tailored to the unique needs of individual patients, leading to improved health outcomes. Additionally, the ability to produce these devices on-demand reduces wait times, ultimately streamlining patient care.

Furthermore, as 3D printing continues to evolve, it presents exciting opportunities for advancements in various areas of healthcare, including prosthetics, implants, and surgical tools. Thus, embracing this technology is essential not only for enhancing the effectiveness of medical devices but also for promoting patient empowerment and satisfaction.

In light of these developments, it is crucial to explore the significant impact of 3D printing on the future of medical devices. By understanding its potential and implications, we can better appreciate how this technology is revolutionizing healthcare and improving lives.

What Are Medical Devices? Understanding Their Importance in Healthcare

Moreover, To fully appreciate the impact of 3D printing, we must first understand what medical devices are. In essence, medical devices are any instrument, apparatus, or machine used to diagnose, prevent, monitor, or treat medical conditions. This broad category includes:

- Diagnostic Devices: Tools like blood glucose meters, X-ray machines, and ultrasound devices that help healthcare professionals identify health issues.

- Therapeutic Devices: Items such as infusion pumps, pacemakers, and prosthetic limbs that assist in treatment or rehabilitation.

- Surgical Instruments: Tools like scalpels, forceps, and suturing devices used during surgical procedures.

- Patient Monitoring Devices: Wearable technologies and monitors that keep track of vital signs and health metrics in real-time.

The importance of these devices cannot be overstated. They enhance the quality of patient care, facilitate timely interventions, and often lead to better health outcomes. For instance, a well-designed prosthetic limb can significantly improve a patient’s quality of life, allowing them to regain mobility and independence. As medical devices continue to evolve, integrating 3D printing technology into their production is becoming increasingly vital.

How 3D Printing Technology is Transforming Medical Devices

So, how exactly is 3D printing transforming the landscape of medical devices? Here are several key areas where this technology is making waves:

1. Customization and Personalization

One of the most significant advantages of 3D printing is the ability to create customized medical devices. Each patient has unique anatomical features and specific needs. With traditional manufacturing, producing tailored solutions can be challenging and expensive. However, 3D printing allows healthcare professionals to design devices that fit perfectly, enhancing comfort and effectiveness. For example, 3D-printed prosthetics can be tailored to match the exact measurements of a patient’s residual limb, ensuring a better fit and improved functionality.

2. Rapid Prototyping

In the fast-paced world of healthcare, time is of the essence. 3D printing enables rapid prototyping, which means new designs can be created and tested quickly. This process allows engineers and medical professionals to iterate on designs based on real-world feedback without the long lead times associated with traditional manufacturing. For example, if a surgeon needs a specialized surgical tool, they can design it in software, print it, and have a prototype ready for testing within days. This agility accelerates the development process and leads to better outcomes.

3. Complex Geometries and Designs

3D printing offers the capability to create intricate and complex geometries that would be impossible with traditional manufacturing techniques. This ability is particularly valuable in the creation of devices like implants and scaffolds used in tissue engineering. For instance, researchers are exploring 3D-printed scaffolds that mimic the structure of human tissue, allowing cells to grow and integrate more naturally. These advancements hold promise for regenerative medicine, potentially leading to breakthroughs in organ transplantation and tissue repair.

4. Cost Reduction

3D printing can significantly reduce production costs. Traditional manufacturing often involves expensive molds and tooling, which can be prohibitively expensive for small-scale production runs. With 3D printing, manufacturers can produce items on-demand without the need for extensive tooling. This efficiency not only lowers costs but also minimizes waste, making it a more sustainable option for producing medical devices.

Benefits of 3D Printing in Medical Devices: Customization and Efficiency

The benefits of integrating 3D printing into medical device manufacturing extend beyond cost savings. Here are some additional advantages:

1. Improved Patient Outcomes

Customized medical devices lead to better patient outcomes. When devices fit properly and meet individual needs, patients experience enhanced comfort, increased satisfaction, and improved functionality. For example, 3D-printed dental implants can be designed to fit seamlessly into a patient’s mouth, reducing discomfort and the likelihood of complications.

2. Shortened Production Times

In urgent medical situations, time is critical. 3D printing allows for the rapid production of medical devices, meaning that healthcare providers can have the tools they need when they need them. This speed can be a lifesaver in emergency settings, where every second counts.

3. Enhanced Innovation

3D printing fosters a culture of innovation within the medical device industry. The ability to rapidly prototype and test new ideas encourages experimentation and exploration of novel solutions. As a result, we are likely to see an influx of groundbreaking medical devices that improve patient care and expand treatment options.

Case Studies: Innovative Medical Devices Created with 3D Printing

Numerous success stories showcase the impact of 3D printing on medical devices. Here are a few notable examples:

1. Prosthetic Limbs

One of the most compelling applications of 3D printing is in the creation of prosthetic limbs. Companies like e-NABLE and Open Bionics leverage this technology to produce affordable, customized prosthetics for children and adults. These devices not only enhance mobility but also empower users to express their individuality through customizable designs.

2. Surgical Models

Surgeons often rely on precise models to plan complex procedures. 3D printing enables the creation of patient-specific surgical models based on imaging data, allowing surgeons to rehearse and visualize the operation beforehand. This preparation can lead to shorter surgery times and reduced complications. For instance, 3D-printed models of heart structures have helped cardiologists plan intricate surgeries, improving patient outcomes.

3. Dental Devices

In dentistry, 3D printing is revolutionizing the production of crowns, bridges, and aligners. Companies like Align Technology use 3D printing to create clear aligners that are customized for each patient’s dental structure. This tailored approach leads to better fit and comfort, enhancing the overall treatment experience.

Challenges in Integrating 3D Printing Technology in Medical Devices

Despite its many advantages, the integration of 3D printing into medical devices is not without challenges. Here are some of the key obstacles the industry faces:

1. Regulatory Hurdles

Medical devices are subject to strict regulatory scrutiny to ensure safety and effectiveness. The rapid pace of 3D printing innovation can make it difficult for regulatory bodies to keep up. As a result, navigating the approval process for new 3D-printed devices can be complex and time-consuming.

2. Material Limitations

While the range of materials available for 3D printing is expanding, there are still limitations. Not all materials are suitable for every application, particularly in medical settings where biocompatibility is crucial. Researchers are continually working to develop new materials that meet the rigorous standards required for medical devices.

3. Quality Control

Ensuring consistent quality in 3D-printed devices can be challenging. Variations in the printing process can lead to inconsistencies in product performance. Developing robust quality control measures is essential to guarantee that each device meets the necessary standards.

The Future of Medical Devices: Trends in 3D Printing Technology

As we look to the future, several trends are emerging in the realm of 3D printing for medical devices:

1. Personalized Medicine

The shift toward personalized medicine will continue to drive the demand for customized medical devices. As healthcare becomes increasingly tailored to individual patients, 3D printing will play a crucial role in developing devices that meet unique anatomical and therapeutic needs.

2. Bioprinting

Bioprinting—the process of using 3D printing to create living tissues—holds immense promise for the future of healthcare. Researchers are exploring ways to print organs and tissues for transplantation, potentially addressing the critical shortage of donor organs. While this technology is still in its infancy, its potential impact on healthcare is profound.

3. Smart Medical Devices

The integration of technology into medical devices is another trend to watch. As the Internet of Things (IoT) continues to expand, we can expect to see more smart medical devices that collect and transmit data. 3D printing will play a vital role in creating the components necessary for these advanced technologies.

Patient-Centric Medical Devices: How 3D Printing Enhances Personalization

The shift toward patient-centric care is at the forefront of modern healthcare. 3D printing is a key player in this trend, enabling the creation of devices tailored to individual patient needs. Here are some ways that 3D printing enhances personalization:

1. Tailored Fit and Functionality

Customized medical devices ensure a perfect fit for each patient. This is particularly important in areas such as orthotics and prosthetics, where comfort and function are paramount. When devices fit correctly, patients are more likely to use them consistently,

leading to better health outcomes.

2. Adaptive Design Features

3D printing allows for the incorporation of adaptive design features. For example, a prosthetic limb can be designed with interchangeable parts to accommodate the patient’s changing needs over time. This adaptability not only improves the user experience but also extends the lifespan of the device.

3. Engagement and Empowerment

Personalized medical devices empower patients. When individuals have devices tailored to their specific needs, they feel more in control of their health journey. This sense of ownership can lead to greater engagement in their treatment and a more positive outlook on recovery.

Conclusion: The Future of Medical Devices and 3D Printing Technology

In conclusion, the future of medical devices is undeniably bright, especially with the ongoing integration of 3D printing technology. As we embrace this innovative approach, we unlock unprecedented opportunities for customization, efficiency, and enhanced patient care. Moreover, the shift toward personalized solutions not only addresses individual needs but also fosters greater engagement and satisfaction among patients.

Furthermore, the adaptability of 3D printing allows for rapid prototyping and the creation of complex geometries, paving the way for groundbreaking developments in medical devices. Consequently, as we move forward, the medical device industry is poised to evolve significantly, driven by technological advancements and a commitment to improving health outcomes.

Additionally, the integration of smart technology with 3D printing holds immense promise. This fusion is likely to lead to the development of intelligent medical devices that can monitor, analyze, and respond to patients’ needs in real time. Therefore, we can anticipate a future where healthcare is not just reactive but proactive, significantly enhancing the quality of care.

Ultimately, embracing 3D printing technology in medical devices is not merely a trend; rather, it represents a fundamental shift in our approach to healthcare. By prioritizing personalization and innovation, we are poised to create a future where medical devices are not only effective but also tailored to the unique requirements of every individual. As we continue to explore this exciting frontier, we can expect remarkable advancements that will redefine what is possible in healthcare.

In essence, the journey has just begun. With 3D printing at the forefront, the potential for improved patient care and innovative solutions is indeed limitless. As we look ahead, we can be optimistic about the transformative impact this technology will have on the medical device landscape, ensuring a healthier future for all.